My Team: Ammaar Landbrug, Mohammed El Massaoui, Ruba Ammiwala

Project: Plastic waste management; Burkina Faso is suffering from a major plastic waste disaster.

The project in short:

Plastic waste is currently one of the most pressing environmental problems.

Plastic waste is being dumped in the cities, rural areas by the industry and is finding

its way to the sea via rivers and canals. All these waste will infiltrate our food change.

To tackle this waste problem, we need to come with a device in which we can recycle

the plastic waste into trading goods. With this device, you and catch two birds with

one stone: The plastic is being recycled to generate some income, and people have

an incentive to collect plastic that has been discarded in the streets. Try to make your

technical solution for today’s waste, tomorrow’s profit!

Our idea:

The conclusion taken after thoroughly reading the assignment is that turning

plastic waste into frisbees is futile; frisbees will eventually turn into plastic waste

again within the span of two years. However, turning the waste into something more

durable and advantageous, such as power outlets, would be beneficial to Burkina

Faso’s infrastructure and economy on the long term. It would take an estimate of

thirty years for the plastic components within a power outlet to cycle back into the

waste disposal system (according to NACHI). In order to create these power outlets

from plastic it needs to melt it into a mold, which is the design that is made.

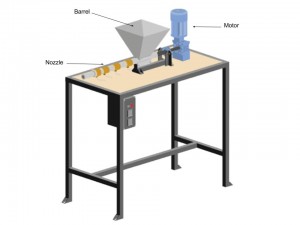

Dave Hakkens’ designs for his “Precious Plastic” project is the base. These

designs are relatively cheap compared to others with a price of approximately two

hundred and fifty euros, and thus perfect for Burkina Faso. The section of the

contraption that is targeted was the extrusion system. Starting by drawing numerous

blueprints for the extrusion. The drawing is on a scale of 2:1.

You can read my reflection and evaluation in my POP

In the appendix here you can see my ‘competentie monitor’